The expected temperature drop through a direct expansion evaporator coil is a crucial factor in the design and optimization of refrigeration systems. This temperature drop is influenced by several factors, including refrigerant type, coil design, and airflow rate. Understanding and calculating this temperature drop are essential for ensuring efficient and reliable refrigeration performance.

In this article, we will explore the concept of the expected temperature drop through a direct expansion evaporator coil, discuss the factors that affect it, and provide guidance on calculating and optimizing this temperature drop for specific applications.

1. Define the expected temperature drop through a direct expansion evaporator coil

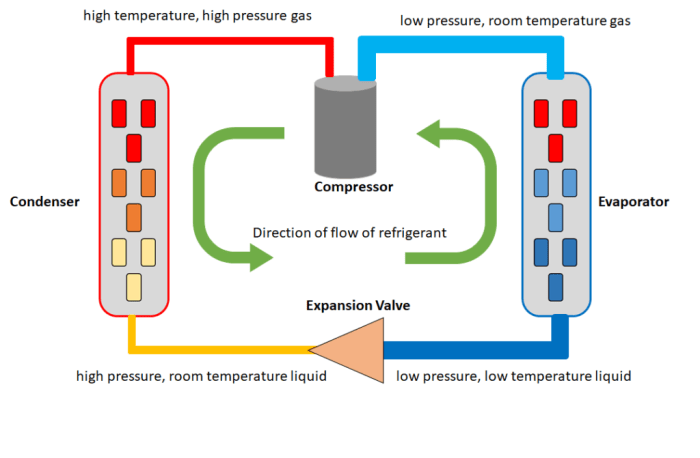

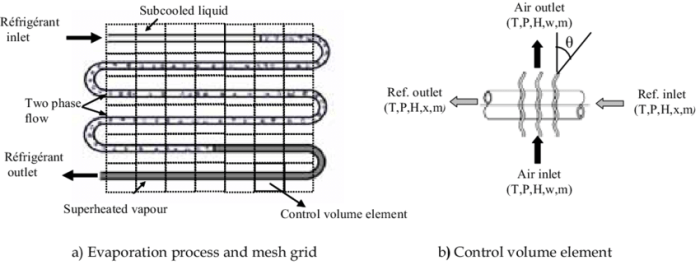

An evaporator coil is a heat exchanger that absorbs heat from a fluid, causing the fluid to evaporate. In a refrigeration system, the evaporator coil is located in the cold space, and it absorbs heat from the air in the cold space, causing the air to cool.

The temperature drop through the evaporator coil is the difference between the temperature of the air entering the coil and the temperature of the air leaving the coil.

Factors that affect the temperature drop through the coil, The expected temperature drop through a direct expansion evaporator coil

- Refrigerant type: The type of refrigerant used in the system will affect the temperature drop through the coil. Refrigerants with a higher latent heat of vaporization will produce a greater temperature drop than refrigerants with a lower latent heat of vaporization.

- Coil design: The design of the coil will also affect the temperature drop. Coils with a larger surface area will have a greater temperature drop than coils with a smaller surface area. Coils with a higher fin density will also have a greater temperature drop than coils with a lower fin density.

- Airflow rate: The airflow rate through the coil will affect the temperature drop. A higher airflow rate will result in a greater temperature drop than a lower airflow rate.

2. Calculate the expected temperature drop through a direct expansion evaporator coil

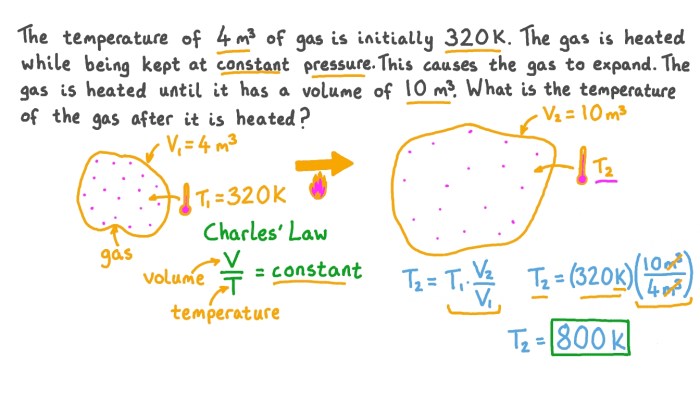

The temperature drop through an evaporator coil can be calculated using the following formula:

$$\Delta T = \fracQUA$$

Where:

- ΔT is the temperature drop through the coil (°F)

- Q is the heat transfer rate (Btu/h)

- U is the overall heat transfer coefficient (Btu/h-ft 2-°F)

- A is the surface area of the coil (ft 2)

The overall heat transfer coefficient is a measure of the ability of the coil to transfer heat. It is a function of the coil design, the refrigerant type, and the airflow rate.

To use the formula to calculate the temperature drop through an evaporator coil, you will need to know the heat transfer rate, the overall heat transfer coefficient, and the surface area of the coil.

3. Design a direct expansion evaporator coil for a specific application

When designing an evaporator coil for a specific application, you will need to consider the following factors:

- Capacity: The capacity of the coil is the amount of heat that it can transfer. The capacity of the coil will be determined by the size of the space that it is cooling and the temperature difference between the space and the refrigerant.

- Efficiency: The efficiency of the coil is a measure of how well it can transfer heat. The efficiency of the coil will be determined by the design of the coil and the refrigerant type.

- Cost: The cost of the coil will be determined by the size, efficiency, and design of the coil.

Once you have considered these factors, you can select an evaporator coil that is appropriate for your application.

4. Optimize the performance of a direct expansion evaporator coil

There are several ways to optimize the performance of an evaporator coil, including:

- Using a high-efficiency refrigerant: High-efficiency refrigerants have a higher latent heat of vaporization, which will result in a greater temperature drop through the coil.

- Increasing the airflow rate: A higher airflow rate will result in a greater temperature drop through the coil.

- Reducing the coil temperature: A lower coil temperature will result in a greater temperature drop through the coil.

By optimizing the performance of the evaporator coil, you can increase the efficiency of the refrigeration system and reduce the cost of operation.

5. Troubleshoot problems with a direct expansion evaporator coil

There are several problems that can occur with an evaporator coil, including:

- Icing: Icing occurs when water vapor in the air freezes on the surface of the coil. Icing can reduce the airflow through the coil and decrease the efficiency of the system.

- Fouling: Fouling occurs when dirt and debris accumulate on the surface of the coil. Fouling can reduce the airflow through the coil and decrease the efficiency of the system.

- Leaks: Leaks can occur in the coil or in the refrigerant lines. Leaks can reduce the efficiency of the system and can also be dangerous.

If you are experiencing problems with an evaporator coil, you should contact a qualified technician to troubleshoot the problem and make repairs.

Popular Questions: The Expected Temperature Drop Through A Direct Expansion Evaporator Coil

What is the purpose of an evaporator coil in a refrigeration system?

An evaporator coil is a heat exchanger that absorbs heat from the refrigerated space and transfers it to the refrigerant.

What factors affect the temperature drop through an evaporator coil?

The temperature drop through an evaporator coil is influenced by refrigerant type, coil design, airflow rate, and evaporator coil temperature.

How can I calculate the expected temperature drop through an evaporator coil?

The expected temperature drop can be calculated using the formula: ΔT = Q / (UA), where ΔT is the temperature drop, Q is the heat transfer rate, U is the overall heat transfer coefficient, and A is the coil surface area.